Welding wire is one of the main materials. It is used for semi-automatic arc welding in shielding gases. The product acts as a universal product of rolled metal products. Outwardly, it is a flexible thread of different lengths and sections. The most popular steel welding wire.

Varieties of wire for welding

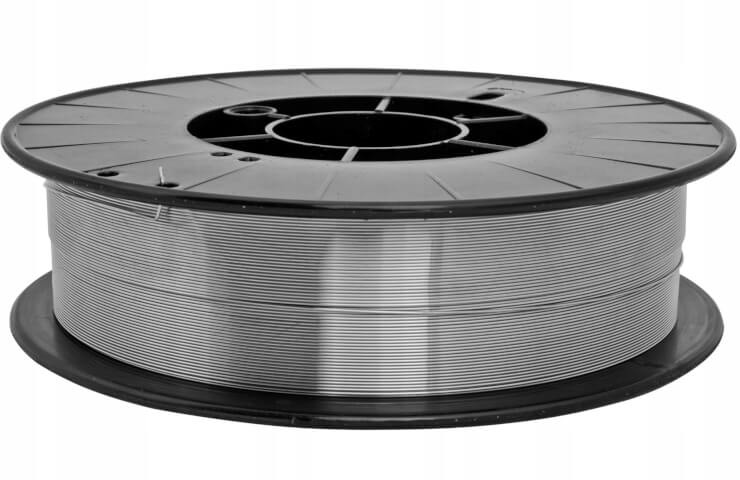

It is delivered in reels, which are placed in the welding machine. Welding wires can be flux-cored, aluminum, copper-plated, stainless, and also steel.

Copper-plated wire is used in arc welding.

Stainless wire is suitable for welding alloy with nickel and chromium. The seam has:

- corrosion resistance;

- Increased service life.

stable and almost no spatter.

There are several classifications by composition, diameter, strength level.

There are many options for a steel product. To weld steel with a small amount of carbon, grades are used:

- Sv-08;

- Sv-10G2;

- St. Yugl.

Grades for medium and low alloy steel:

- Sv-08G2S;

- Sv-18XS;

- Sv-08GS.

For high-alloy steels, product grades are suitable:

- Sv-12X13;

- Sv-08X14GNT.

Aluminum product used in production:

- cars, motorcycles;

- ships, boats, etc.

Suitable for welding aluminum and alloys. This contributes to the strength of welded joints. Their corrosion resistance is noted.

Welding wire usually includes additives. If there is titanium 0.1 or 0.2%, then this allows the welder to make a fine-grained seam. It is often required for the most accurate work.

In accordance with GOST, aluminum wire without inclusions is in a separate category. In addition to it, there are alloys with:

- copper;

- magnesium.

Features of flux-cored wire

Special mention should be made of flux-cored wire. It is used for semi-automatic welding.

The differences are easy ignition and stable arc burning.

No need for a gas bottle. Metal welding occurs without much difficulty. There is a flux inside. During combustion, it forms a gas cloud.

During the wire procedure, you can:

- hold in hand while feeding into the welding area;

- throw into the feeder.

There are filler products that do not require the use of protective gases, for example, welding wire e71t gs. It is used for welding carbon steels.

Cored wire is intended for single-pass welding. There is no protective atmosphere. The product is often purchased for welding various elements. It is suitable for connecting different elements. Indispensable for a variety of metal structures.