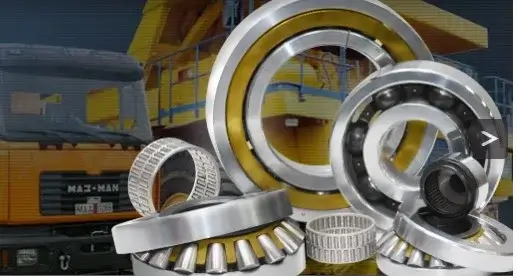

To reduce the negative impact of friction during the rotation of parts, many technical solutions have been invented. But the bearing https://gpz1.ru/ is considered to be the best and most effective. Taking on a variety of static and dynamic loads, it reduces the friction indicator to a minimum value. Universal industrial bearings have found their niche in almost all areas of mechanical engineering.

Feature of the production process

Roller and ball bearings belong to the category of universal bearings, as they can be used in practice in almost any industrial mechanisms. The company produces a wide enough range to satisfy the demand for products from numerous production and assembly plants. The main areas of use of the products are:

- Companies specializing in the manufacture of mining equipment.

- Design and manufacture of conveyors, transport belts.

- Repair shops a wide variety of industrial equipment.

- Manufacture of agricultural and specialized equipment.

- Bearings are used in aircraft and helicopter manufacturing.

On the quality of produced ball and roller bearings bearings depends on how long and trouble-free the mechanism or its individual unit will operate. Accuracy is especially important when using large diameter parts with significant load on balls or rollers. Particularly important are standardized products produced in medium or large quantities for the domestic market.

Causes of premature wear

If you follow the recommended loads, rotation speeds and use suitable oil for lubrication, the bearing will last long enough without the need for replacement or clearance adjustments. But, in practice, various unforeseen situations occur that lead to wear and even destruction of the bearing during rotation of the parts relative to each other:

- excessive load on the rollers or balls in the cage;

- li>absence or insufficient amount of lubricant;

- overheating of the bearing during prolonged operation;

- foreign objects get into the separator, rollers or balls;

- increased abrasiveness of the medium operation of the part.

The last factor arises in cases where the mechanism is not serviced in a timely manner and a large amount of wear products accumulates in the lubricant. Changing the grease or lubricant is a basic bearing maintenance responsibility in any machine.