Return valve (check valve) - a type of shut-off device that prevents interruptions and leaks in water, sewer, gas and air systems. This is a device that directs the flow of liquid, gas or air in one direction and blocks reverse flows in emergency situations during system failures. Such a valve allows you to protect installations from hydraulic shocks and breakthroughs in supply systems.

The main areas of application of these valves:

- Water supply, heating, sewage systems.

- Branching of pipes of various structures.

- Gas pipes.

- Ventilation systems.

The principle of operation of the check valve

The system of operation of the check valve is quite simple: a certain medium (liquid /gas /air flows), passing through the system, creates pressure on the supply elements, thereby raising the locking element. In case of emergency interruptions, the pressure in the system drops, returning the damper to its original position and blocking the passage of liquid or gas in the supply system.

Main types of check valves

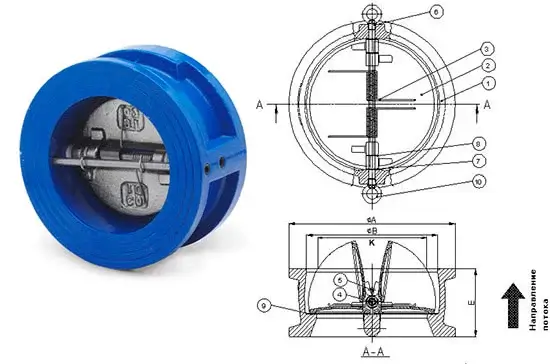

Depending on the type of valve, different types are used locking elements:

- with ball valve;

- with butterfly valve;

- with butterfly valve;

- spring;

- double-leaf valve.

They also differ in materials: valves are made of cast iron (quite rare models, mainly can be used in industrial applications), brass (durable models that do not corrode) and steel (expensive but reliable option for all supply systems). Also, the materials are different for the shutters: there are metal and plastic models. Sealing materials can be made of rubber, plastic or hard alloys.

In addition to the materials of manufacture, valves are divided into non-return and non-return valves - their difference is in the forced actuation of the system.

Where and when you need use check valves?

Any supply systems in residential, public or industrial buildings require protection to avoid emergencies.

Check valves are widely used to ensure uninterrupted stable operation of water systems, prevent leaks household appliances, pipe breaks. Such products are also used when connecting a private residential building to wells using pumps. In ventilation systems, the return valve allows you to control the exhaust air, directs the flow of air masses without returning them back to the system. In forced ventilation systems, a valve is installed to prevent air from entering the overall system. If more complex engineering structures are used, then a valve is installed in the air duct at each branch of the pipeline.

In addition, this system is used to prevent backflows and for gas - such a device reduces gas consumption, and also serves as a fire arrester .

How to choose and install a valve

It is necessary to choose a device based on the purpose of the supply system and the required tasks. Installing a check valve in any case will help prevent emergency situations and greatly facilitate the service of all domestic and industrial units. Mount such pipeline elements in accessible places , for quick and easy maintenance of the system. Thanks to a wide range of locking devices, it is possible to choose the right option for any budget and for any purpose.