Australian Government Research University (RMIT) PhD Jimmy Toton has received the 2019 Young Defense Innovator Award at the Avalon International Air Show. He developed steel for 3D printing tools capable of cutting titanium. Toton did his research with the Defense Materials Technology Center and industry partner Sutton Tools at the RMIT Manufacturing Center.

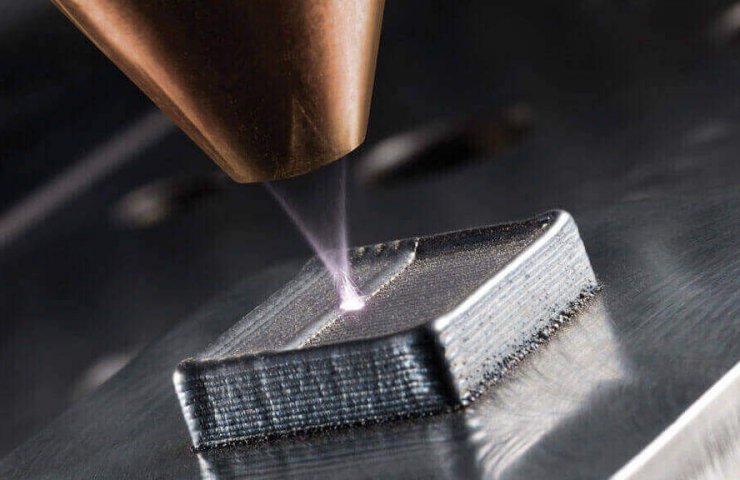

3D printing will allow you to create high-strength tools of increased complexity. Producers will benefit from both monetary and time value. Usually, such tools are made of high-speed steels, and Toton created his material on the basis of cast iron and a carbon-free alloy of cobalt, iron, molybdenum. The resulting material surpasses the properties of high-speed steel.

Toton began creating his high-strength material, realizing how difficult it is to cut metals that are used in the aerospace and defense industries. Requirements for the strength of materials are constantly growing, and, consequently, their price is also growing.