Engineers American automobile company Tesla izobreli new aluminum alloy that can maintain high yield when using the technology of injection molding of parts of electric vehicles. This is stated in the patent application of the company.

the Development of new alloys began in 2016, when Elon Musk hired expert its alloys Charles Quemanda, he also headed the departments of new materials in Tesla and SpaceX.

In the application for patent Koeman describes the problem of existing aluminum alloys, which they are trying to solve:

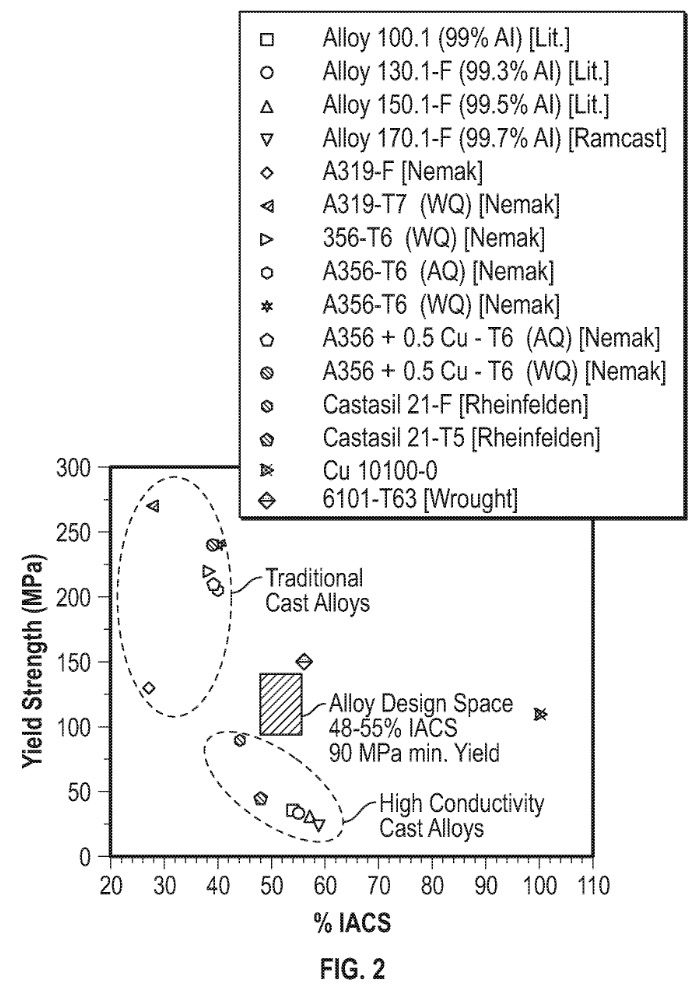

"Commercial cast aluminum alloys fall into one of two categories - either have a high yield strength or possess high conductivity.

for Example, A356 aluminum alloy has a yield strength of 175 MPa, but has a conductance of approximately 40% electrical conductivity (IACS). Conversely, 100.1 aluminum alloy has a conductivity of more than 48% IACS but the tensile yield strength less than 50 MPa.

For certain applications, for example, in electric vehicles such as the rotor or inverter, is desirable as high strength and conductivity".

So Tesla is trying to create alloys with high yield strength and specific conductivity, at the same time resistant to hot tearing, for use in the components of the drive device for die casting.

compared to the numbers listed above, Tesla says that its new aluminum alloys can be tuned to achieve the yield strength from 90 MPa to 150 MPa and an electrical conductivity of 40% IACS 60% IACS.

They also argue that the new alloys can be used in the casting process under pressure.