Sibkabel JSC, (part of the Cable Alliance Holding, which unites the cable assets of UMMC), acquired modern equipment for high-precision research of the characteristics of materials and finished products. A universal video measuring microscope is installed in the quality service of the plant, and a tensile testing machine in the chemical and environmental department.

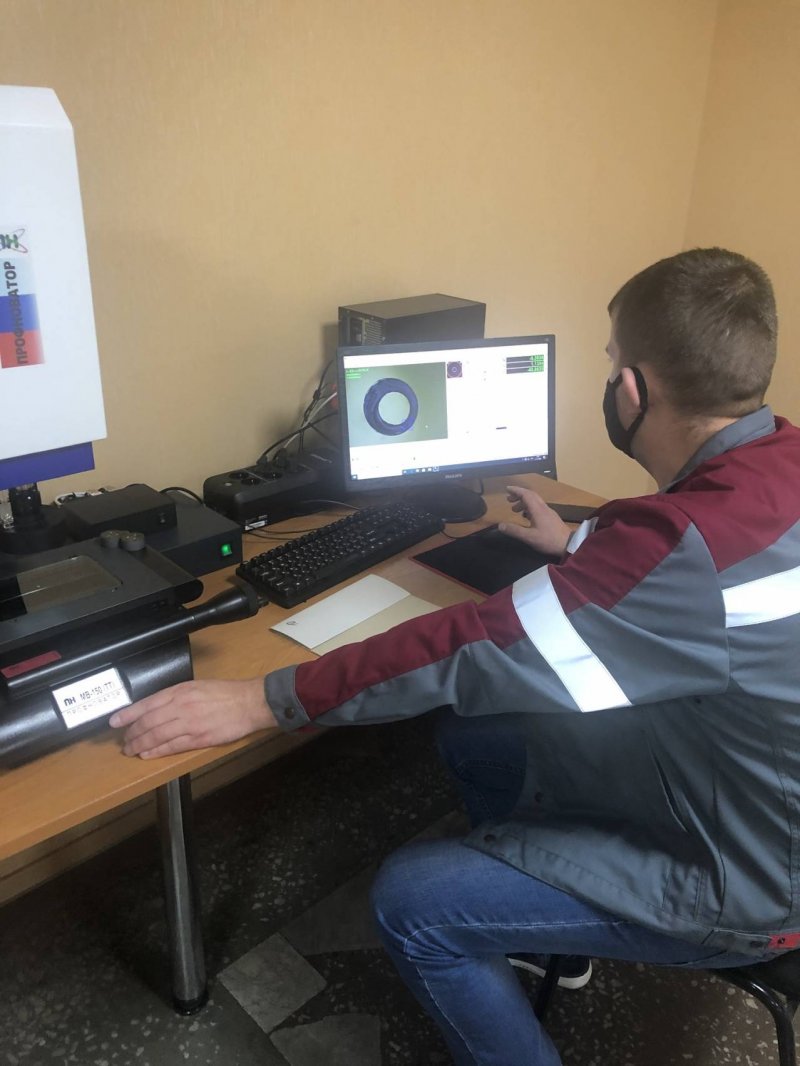

Geometric parameters of cable samples are measured using a microscope. The digital zoom reaches 310x. All necessary parameters are measured within 5 minutes - the information is displayed on a computer monitor in the form of a model drawing.

“Modern equipment measures the diameter of the insulation and sheath with an accuracy of 0.0001 mm, scans the contours of the product to determine the symmetry of the circle (the cable must be perfectly round). In addition, the device allows you to consider any inclusions and damage in the structure, oxidation of copper or aluminum wire. If a defect is detected, the microscope can determine at what stage of production it occurred in order to eliminate an error in the future, ”explained Alexey Bolotnikov, head of the technical bureau of Sibkabel JSC.

A tensile testing machine installed in the chemical-environmental department checks incoming materials for tensile strength and elongation. The most durable are PVC materials used in the production of power, control cables and installation wires. If earlier engineers performed the necessary calculations manually, now data on the physical and mechanical properties of materials are automatically entered into a computer and processed, which doubled the speed of the analysis of one sample.

“The process of improving the quality control of materials and finished products is continuous mode. This applies to the improvement of both technological processes and various studies. This allows us to move towards absolute product quality, which in turn guarantees the timely fulfillment of all orders and the opportunity to participate in the implementation of federal-scale projects, ”said Alexey Zhuzhin, director of Sibkabel JSC.