A wide variety of equipment is used to crush rocks and construction rubble. Each mechanism has its own advantages and disadvantages. Properly selected stone crusher will make it possible to produce cobblestone on a small and industrial scale , crushed stone and screenings for construction needs. Properly selected equipment will allow you to get the necessary material at minimal cost.

A variety of designs

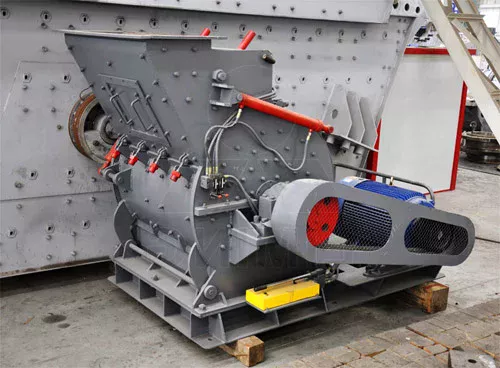

Depending on the type of physical impact, all crushers are divided into several categories. Each has its own advantages and unique technical characteristics. The most popular are structures where the raw material is subjected to compression and splitting to the required size. But, in general, the industry produces the following crushers:

- Jaw crushers, can handle large diameter and high strength stone.

- Conical structures for medium strength rocks.

- Roll crushers capable of producing crushed stone at maximum speed.

- Hammer design designed for the most fragile raw materials.

Structurally, equipment can have a wide variety of sizes. The productivity and speed of processing raw materials into crushed stone of the required size depends on this.

Practical application of crushing equipment

The stone crusher is most in demand in the quarry extraction of natural stone. It is often used by construction organizations to recycle unclaimed or damaged building materials into quarrystone suitable for use when pouring the foundation. In addition, sufficiently strong and reliable crushing equipment is used in other areas of human life:

- in metallurgy for the preparation of auxiliary rock during melting;

- in the chemical industry to obtain raw materials of the required gradation;

- to create bulk dams and dams of a simple and complex type;

- In the cement industry, a quality crusher is indispensable.

All installations, without exception, mechanically act on stone raw materials in order to achieve the required material size by squeezing or abrasion. It is for this reason that crushers have additional protection against accidental release of separately breaking off pieces of raw materials. The safest, from this point of view, are rotary stone crushers.