Termoflow dry coolers: operating principle, savings and 5 key selection criteria for your production

Cooling towers are widely used in many industrial fields. They are used to cool recycled water and effectively remove heat from process equipment, for example, in air conditioning systems. The most economical option for industrial operation is considered to be a dry cooling tower, which cools the coolant due to atmospheric air. The installation is energy efficient, has low operating costs and does not require complex maintenance and maintenance.

What is a draycooler?

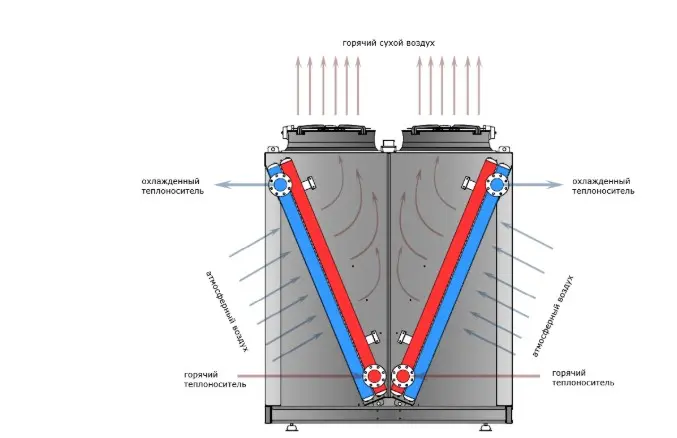

A dry cooler is a liquid cooler that uses air from the street to operate. To give an analogy, it looks like an external unit of an air conditioner designed to divert heat to the outside to keep industrial equipment running. The fundamental difference between the device and a wet cooling tower is the method of cooling the coolant, in which the dry cooler uses air without contact with water.

The principle of operation and the main advantage is huge savings.

The operation of the dry cooler is based on the use of natural cold. During the operation of industrial equipment, the coolant circulates through the system and is cooled using cold air, which is supplied through a heat exchanger by means of fans.

The key advantage of using a draycooler is serious savings. Unlike a wet cooling tower, the device does not use water evaporation processes, which allows the company to reduce water supply costs. In addition, the equipment does not use a compressor, and this provides a noticeable reduction in electricity costs.

Areas of application: where are draycoolers indispensable?

Dry coolers are used in chemical, energy, pharmaceutical and other fields. They are used to cool water, process fluids, and hydraulic oil, as well as to maintain a set temperature in various production processes. The devices work most effectively in tandem with such equipment.:

- refrigeration units;

- Hydroelectric power station, thermal power plant;

- heat pumps;

- industrial cooling;

- Data centers (data processing centers).

Selection plan: 5 key criteria for your project

The choice of a draycooler should be based on the specific operating conditions. When ordering a device, the following criteria must be taken into account::

- Thermal load and cooling temperature. The installation capacity is calculated using a special formula that takes into account