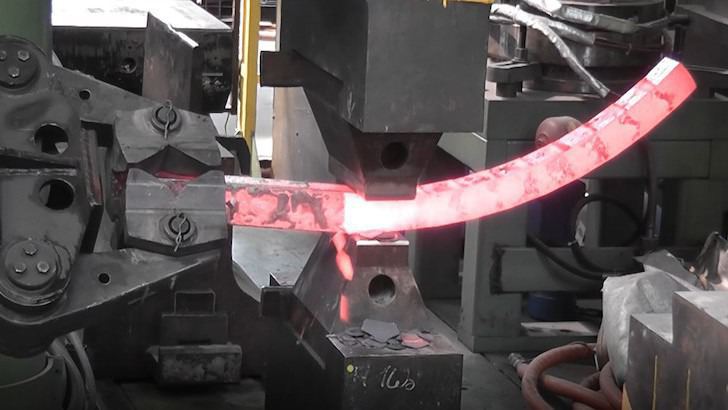

Metal processing by pressure method (stamping, press for shaping, rolling) belongs to the category of rather complex production processes, which require:

- Special high-tech, complex and expensive equipment.

- A staff of qualified technologists, adjusters and machine operators capable of drawing up a flow chart for the manufacture of products by this method, as well as adjusting the equipment (machines) accordingly.

Such a force (physical) effect, in contrast to the methods of using cutting machines, excludes the formation of a waste part (chips) and a change in the metal structure as a result of exposure to high temperatures arising during processing. In order to order metalworking (production of a part with specified parameters) using the pressure method, the customer does not need to have a detailed technical description (steel grade, shrinkage tolerances) and product drawings. Experienced technologists with the help of special software will develop all the necessary documentation using:

- Sample available (for example, gear from imported equipment).

- Technical characteristics of the device (mechanism) for which a particular part is made.

- Values of power loads that the part will experience during operation.

After that, the prepared technological map will be sent to the equipment installers to start the technical procedure for making an order. In this case, consumables can be provided by the customer or purchased from suppliers.

The main advantages of the metal forming method

Despite the difficulties that arise during the adjustment of equipment for obtaining products from metal using the pressure method, the process itself is one of the fastest and most efficient (for example, one stroke of a stamping press - one finished part).

Professionally adjusted work and modern equipment guarantee high quality and compliance with the parameters specified by the customer. To obtain more complete information on the technical possibilities of using the metal pressure method for obtaining a certain type of product, please visit the website of a company that provides this type of service using its own production facilities.