Canadian company Valbruna ASW Inc. a leading regional manufacturer of specialty steels to build a fully automated metal casting line at its site in Welland.

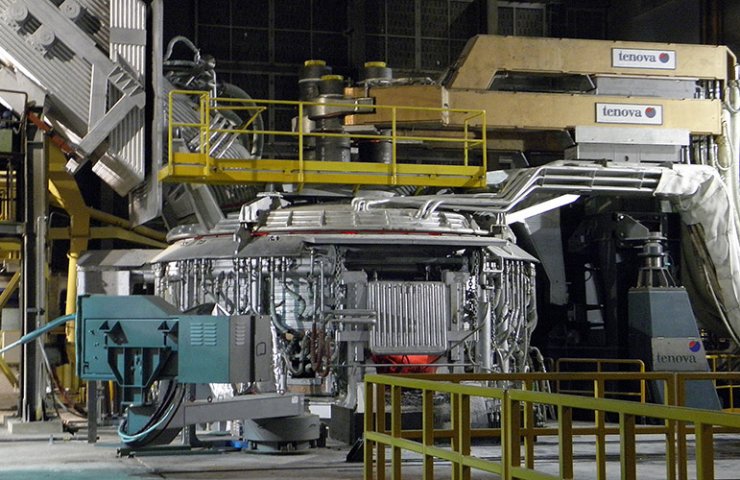

The electric arc furnace (EAF) equipment will be supplied by Tenova, which will also provide related ancillary equipment, a handling system including bin batteries, bins and conveyor belts for bucket loading, as well as the entire automation system.

The complete management of this plant will be fully automated and integrated into a new process control system.

Thus, the new EAF will guarantee an increase in the hourly productivity of the smelter, as well as the efficiency and reliability of the production of high quality steel and stainless steel.

The new automation system offers a number of advantages that significantly increase the level of plant efficiency. In particular, this guarantees a correct and efficient work cycle for the production of different steel grades. It also optimizes operating parameters and production data storage. In addition, the safety of operators in the plant is greatly enhanced and the system meets the most stringent safety standards.

The new electric arc furnace will be equipped with the modern Tenova TDRH 4.0 electronic control system (Tenova digital electronic control). TDRH 4.0 can significantly reduce power consumption and provide excellent arc stability. This updated version has additional functions, mainly for self-diagnostics, troubleshooting and automatic calibration (self-learning) and adjustment of control parameters.

“The plant will set the North American technological benchmark for stainless steel,” said Marco Longobardo, Digital Product Manager at Tenova.