Modern metalworking is impossible without high-quality forming of workpieces of the required shape. The process of bending products under pressure without destroying the structure allows you to create durable and precise elements for various structures. Today, this method is actively used in the manufacture of metal structures made of stainless steel, aluminum, copper and other alloys.

The main technologies of metal forming

Modern enterprises use several types of technologies, differing in the method of impact and scope of application.

- The mechanical method. It is made using presses and rollers, suitable for large-scale production of parts of the same radius.

- The hydraulic method. It is based on a uniform pressure distribution, ensures accuracy and the absence of cracks on the surface of the workpiece.

- Using CNC. Computer control guarantees high angle accuracy and repeatability in mass production.

- Roller forming. It is used for long products, such as profiles and pipes, when dimensional stability is required along the entire length.

Bending of pipes and profiles: technology features

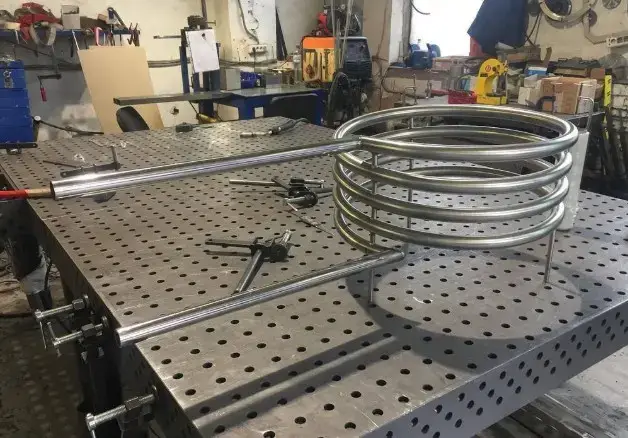

Working with pipe blanks has its own nuances. When bending stainless steel pipes, it is important to consider the wall thickness and bending radius to avoid deformations. For such operations, mandrel equipment is used to preserve the shape and internal cross-section.

The round tube is bent using special machines with adjustable rollers, which ensures a neat and precise bending without wrinkles.

Bending a metal profile requires a different approach – profile elements are often bent radially using sectional rolls to achieve a smooth bend without damaging the corners.

Features of sheet metal bending

When working with sheet workpieces, both manual and automatic technology is used. Sheet metal bending is more often performed on CNC machines, which ensures the perfect geometry of the parts. For non-standard tasks, custom sheet bending is in demand, where individual radii, angles and materials are taken into account.

Companies specializing in the production of stainless steel metal structures often combine bending with cutting and welding, which allows them to create products with a minimum number of joints and increased strength.

Calculation and selection of technology

Before starting work, metal bending is calculated, which takes into account the thickness of the material, its elasticity, radius and fiber direction. Based on this data, it is selected